CERTIFICATES

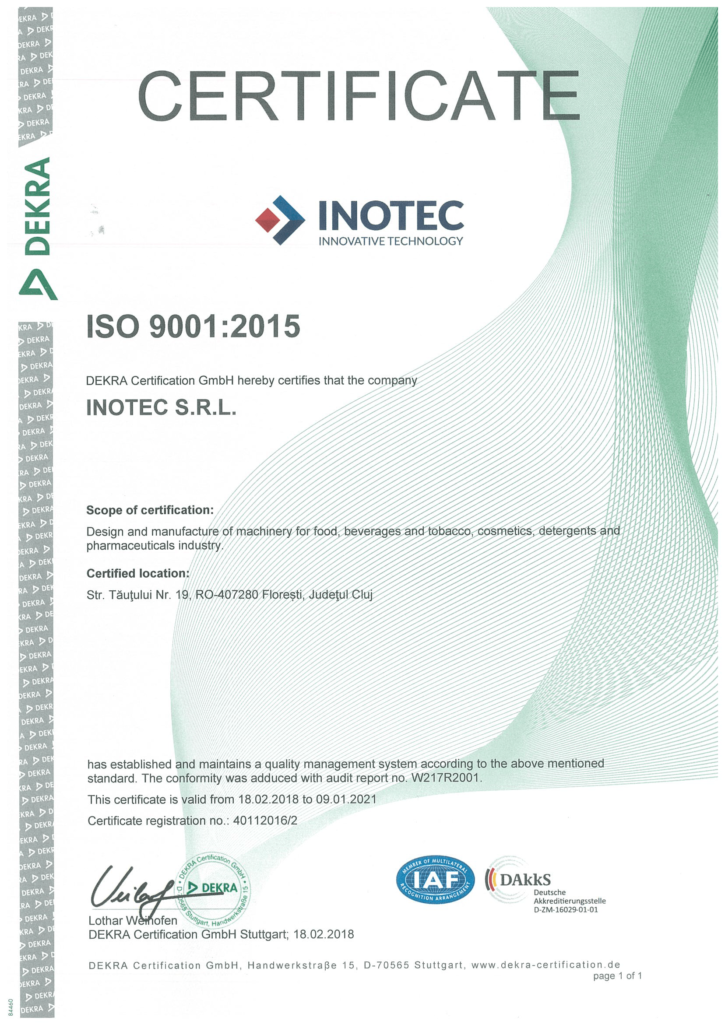

CERTIFICATE ISO 9001:2015

ISO 9001: 2015 Certification of Inotec is achieved for “Design and manufacturing of machinery for food, beverages and tobacco, cosmetics, detergents and pharmaceutical industry” and is done by the accredited and licensed organization DEKRA Certification GmbH.

The aim of the certification is to establish, implement and maintain a quality management system in accordance with the ISO 9001: 2015 standard in our bussines profile. By ISO 9001: 2015 certification, Inotec organization scope is:

a) To demonstrate its ability to consistently provide products and services that meet customer and applicable statutory and regulatory requirements, and

b) To enhance customer satisfaction through the effective application of the system, including processes for improvement of the system and the assurance of conformity to customer and applicable statutory and regulatory requirements.

CERTIFICATE EN ISO 3834-2

ISO 3834-2:2005 Certification of Inotec defines comprehensive quality requirements for fusion welding of metallic materials both in workshops and at field installation sites and is done by accredited and licensed organization TÜV SÜD Industrie Service GmbH.

Inotec is certified according to EN ISO 3834-2 for the following ranges:

a) Scope of production: Pressure vessels and parts of them, Heat exchangers and Boilers

b) Base of material(s): Steels of the group 1 and 8(Group(s) according to EN ISO/TR 15608)

c) Dimension of items: Thickness up to 40 mm, max. length 12 m,max. Ø 4,0 m

d) Welding process:(Process numbers acc. to EN ISO 4063) 111 Manual arc welding, 141 TIG welding with solid filler material (wire/rod)

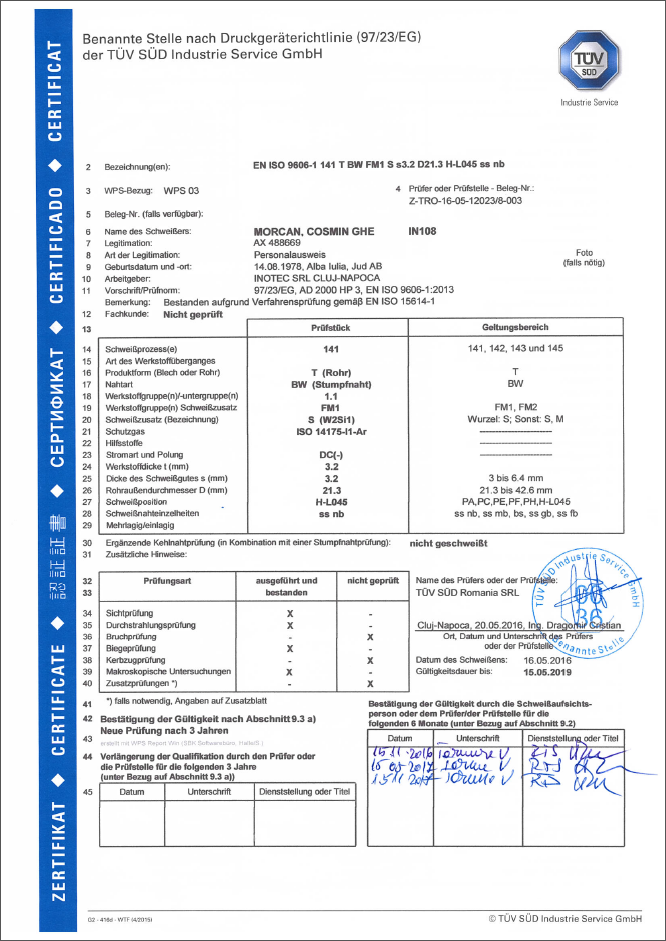

CERTIFICATE EN ISO 9606-1

EN ISO 9606-1:2017 Certification prove the ability r to follow written instructions, skills and qualification testing of Intec’s welders for steel (stainless and mild) fusion welding and is done by accredited and licensed organization TÜV SÜD Industrie Service GmbH.

Inotec welders are certified according to EN ISO 9606-1:2017for the following variables and qualification ranges:

a) Material: steel (stainless and mild)

b) Welding proceses: 141 TIG welding with solid filler material (wire/rod)

c)Product type: plate and pipe

d) Type of weld: butt

e) Materials thickness: up to 10 mm

f) Outside pipe diameters: up to 800 mm

CERTIFICATE PED, EN 13445-4, AD2000

PED 2014/68/EU, EN 13445-4, AD2000 Certification of Inotec is achieved for design, manufacture and conformity assessment of pressure equipment and assemblies with a maximum allowable pressure greater than 0.5 bar and is done by accredited and licensed organization TÜV SÜD Industrie Service GmbH. Pressure equipment means pressure vessels, piping and assemblies, steam boilers, safety and pressure accessories.

Inotec implements a quality assurance system (QA-system) in accordance with the Pressure Equipment Directive 2014/68/EU, the local and international standards to prove the quality performance as a manufacturer. According to the certificate, Inotec:

a) Has facilities permitting manufacturing and inspection in compliance with the technical standards

b) Operates a quality system which guarantees that manufacturing andinspection of the products stated in our report are in conformity withthe technical rules and standards

c)Employs qualified supervisory and inspection personnel

d) Has the welding suitability for manufacturing pressureequipment according standards

ASME Certification

INOTEC SRL is authorized by the American Society of Mechanical Engineers (ASME) for pressurized vesells manufacturing.

Certification for shop location only with scope of activity in accordance with the applicable rules of the ASME Boiler and Pressure Vessel Code.

PART OF THE STATEMENT OF POLICY

0.1 Quality Control System is described to be followed at INOTEC SRL, for the shop construction of pressure vessels and parts to be marked with U Designator according to ASME Boiler and Pressure Vessel Code Section VIII Division 1 requirements

0.2 The Management of INOTEC SRL is totally committed to meet all of the requirements of the ASME Boiler and Pressure Vessel Code